This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Supply chain risks and COVID-19

The effects of the COVID-19 outbreak have generated extensive business continuity challenges for many organisations; at the forefront for many is the risk affecting suppliers’ delivery capability. There are many root causes for this, for example:

- Absence of key production and/or distribution personnel

- A change in prioritisation

- Production halts due to localised social distancing regulations

- Closed borders

When combined with optimised ”just-in-time” delivery and complex, global supply chains, these factors have swiftly led to significant effects not only at the operational-level, in terms of production disturbances, but also financially as organisations fail to deliver to customers, resulting in unavoidable revenue loss.

Clearly, organisations face short-lived challenges to their supply chain every day and effective Business Continuity Planning will deal with immediate problems. However, when faced with a significant and persistent threat, a close, detailed examination of the potential exposure to these disruption risks must be initiated. Based on our experience, we recommend conducting a three step review to mitigate supplier risks.

1. Identify your most critical resources and services and their respective suppliers.

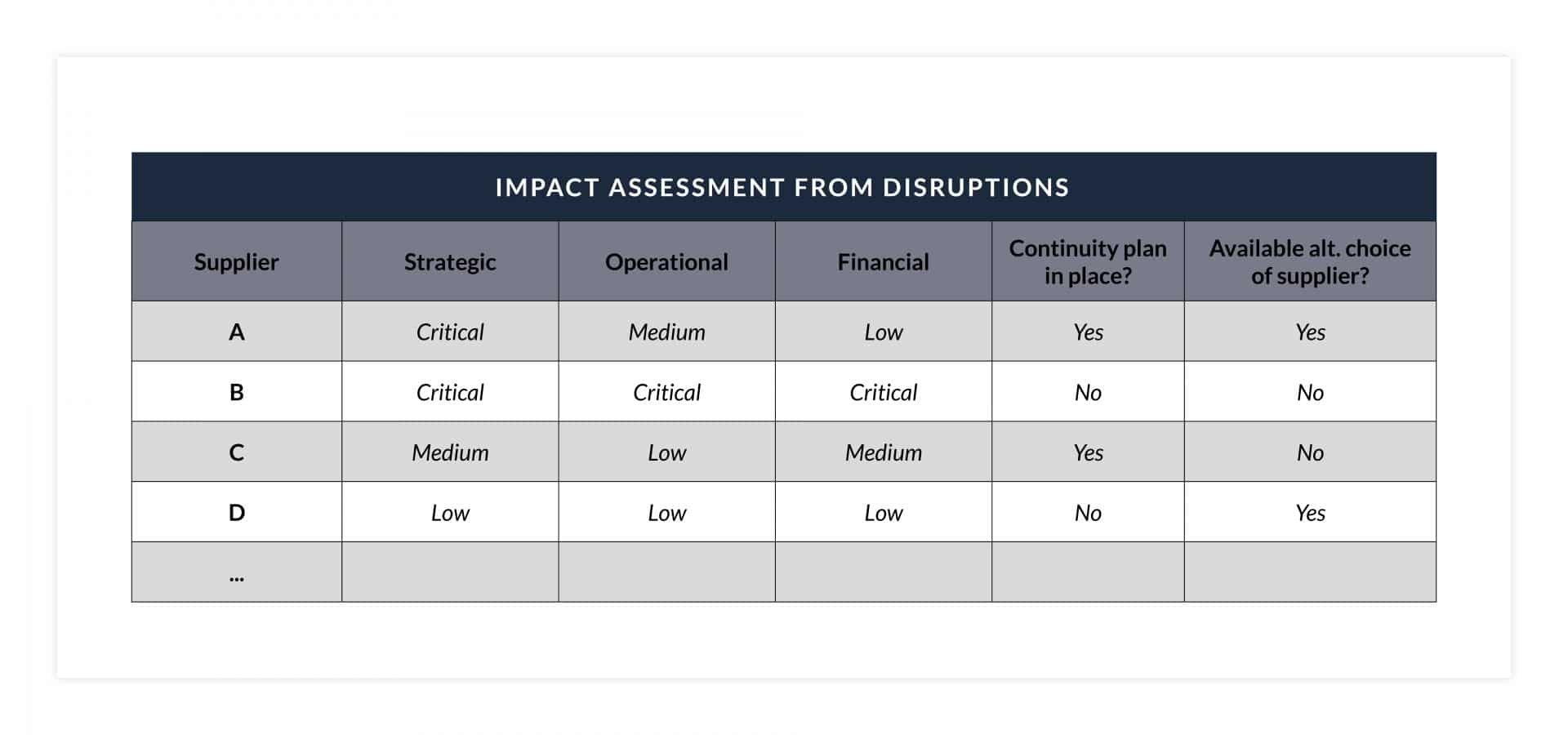

- In order to prioritise appropriately, an initial consequence assessment of supplier disruptions from your operational, strategic and financial perspectives can be useful, as articulated in the template below.

- Review your consequence analysis, risk assessments and continuity plan and check if these suppliers’ risks have already been explored. If not – update!

2. Immediately make personal and direct contact with the prioritised suppliers and initiate frequent follow-ups.

- Clarify that mutual support between supplier and receiver in handling the situation will, undoubtedly, be of benefit to both.

- Relying only on ‘business as usual’ could be a mistake.

- It is key to understand how the supplier has assessed and is managing their operations within the context of the situation. What are the supplier’s key indicators?

- If your contract allows it, make a site visit with your own personnel or with local partners to inspect activities critical to your order/business.

- Continue close contact and mutual follow-up

3. Review your business continuity strategies to uphold operations during partial or full supplier disruptions.

- Existing stock and reserve stock capacity of critical products or raw materials (inhouse or at external partners’) must be examined and reassessed.

- Backup for single-source suppliers must be identified and alternative logistics must be analysed.

These steps highlight that managing supplier disruption risk is not exclusively a procurement department’s issue. Clearly, they could effectively coordinate activities and execute parts of them; however active support from other departments such as Production, Logistics, Risk/Continuity Management and Legal is essential for delivering an effective plan and appropriate response.

The simple template below could be used to map out a basic overview of supplier risks in regards to COVID-19.

For more about COVID-19 and business continuity, visit our COVID-19 portal or download the 4C resources below.

Download Resources

COVID-19 IT Security Remote Working Tips

Download resourceBusiness Continuity Plan for Personnel Dependencies

Download resourceCOVID-19 Mid Incident Review Support

Download resourceCOVID-19: Example of 4C Facts and Assumptions Model

Download resource

Coronavirus Response

Get in touch to speak to a risk management expert about mitigating the impact of COVID-19.